Historical

Invocon, Inc. participated as subcontractor to Penn State Advanced Research Laboratory in the Advanced Capabilities Initiative (ACI) sponsored by the Office of Naval Research. The system was designed for the U.S. Navy to perform remote machinery diagnostics and prognostics in Condition-Based Maintenance (CBM) applications.

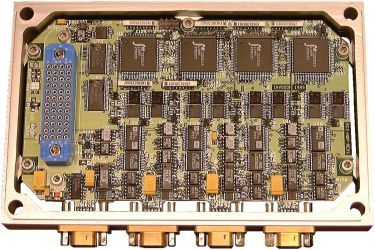

Invocon designed, developed and fabricated the hardware delivered in the final system to the Navy. The system was capable of multi- channel, high-speed data acquisition, remote digital signal processing, and radio frequency communications utilizing a smart network topology. The system consisted of multiple Remote Data Acquisition Units (RDAUs) and a Central Network Unit (CNU).

The Remote Data Acquisition Unit consisted of a power-conditioning module, multiple four-channel high-speed Data Acquisition and Control Modules (DACM), a Dedicated Diagnostic Processing Module (DDPM), a Network Control Module (NCM), and a Spread Spectrum Transceiver Module. The Central Network Unit (CNU) consisted of a power-conditioning module, a Network Control Module (NCM), and a Spread Spectrum Transceiver Module. The CNU Network Control Module contains an IEEE 1284 parallel interface, an RS-232 serial interface, and an RS-485 serial interface.

Communications between units occurred automatically via embedded C routines that can be initiated by the user code. Message routing was automatic without user intervention. The DDPM was provided with an application-programming interface (API) for ease of algorithm development and installation. Algorithms could be developed on-board the DDPM using third party development tools.

The hardware was modular in the sense that functional modules simply stack on each other and were connected via a common bus. Four-channel, high-speed Data Acquisition and Control Modules (DACM) were available for piezoelectric accelerometers, pressure transducers, and general purpose signals.